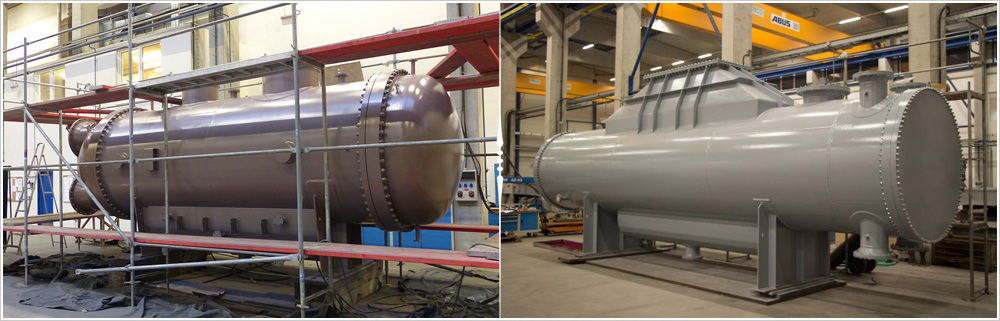

Water-cooled shell and tube heat exchanger installed on the exhaust steam from a steam turbine in thermal power stations. The function of a surface condenser is to create the lowest possible turbine or process operating back pressure while condensing steam. The condensate generated is usually recirculated back into the boiler and reused as boiler feedwater. Both of these operations are accomplished at the best efficiency consistent with the ever-present problem of economy. It imparts to power generation plant a higher thermal efficiency. Our knowledge allows for an expedient, accurate design and fabrication process. Using design methodologies and practices that have been honed over time, we work closely with our customers to evaluate options that best meet each project’s objectives.

Technical parameters and important details :

⦁ Weight of single shell up to 80 tons

⦁ Diameter of the shell up to 3,5 meters

Design of Surface Condensers :

⦁ HTRI (ASPEN+)/ HTFS

⦁ HEI