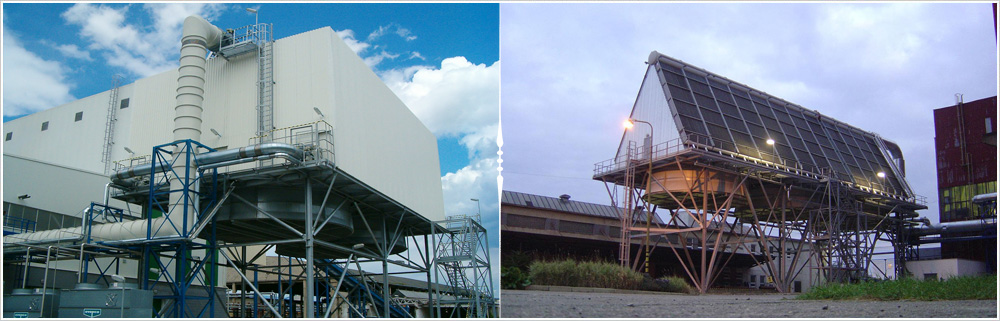

Electricity production processes result in emissions of low-potential heat into the atmosphere. Air-cooled Condensers (Heat Exchangers) use corrosion-free media at low pressures (water steam, water and glycol mixtures). In many cases cooling of extreme thermal powers is needed. This includes cooling of gas and diesel engines, gas and steam turbines and condensation of the emission steam of steam turbines. More and more, air-cooling replaces water-cooling in power engineering, where it is used a standard as water is rarer in some industrial areas and more expensive. In many areas which require the production of electricity, water sources are lacking and in concentrated industrial areas where water is available, its price is very high.

Typical scope of supply, including accessories :

⦁ ACC (tube bundles and steel structure)

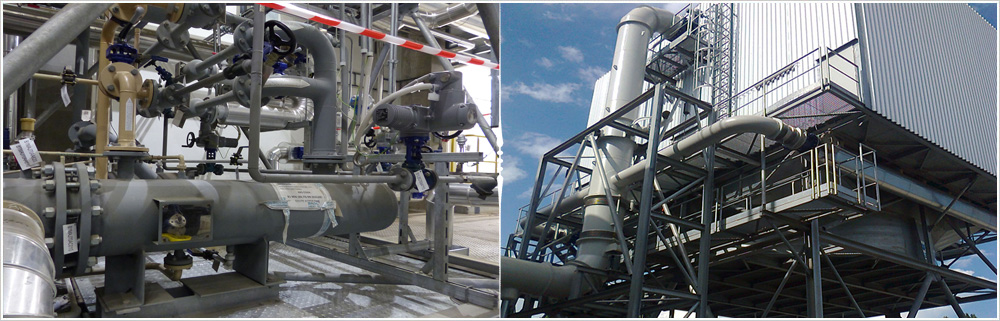

⦁ Air evacuation system (Steam jet ejectors, water ring vacuum pumps)

⦁ Condensate tank

⦁ Condensate pumps

⦁ Steam duct between TG and ACC

⦁ Internal piping, including valves

⦁ Electric supply (switchgears, cables, etc.)

⦁ I & C system

⦁ Assembly on Site, commissioning

⦁ Documentation

Dephlegmator :

During winter period the air-cooled condenser can be operated at a dephlegmator connection if the real steam flow is lower then the safety anti-freezing steam flow. The dephlegmator connection (not included in the scope of supply) in such case will make the continual turbine operation possible without a risk of air-cooled condenser freezing by the condensate. Without a dephlegmator connection it can be operated only with the minimum safety steam flow.